Table of Contents

1. Introduction

2. Material Deep Dive: Construction and Core Properties

3. Metal Push Button Switches: Engineered for Durability

4. Plastic Push Button Switches: Balancing Cost and Functionality

5. Durability and Lifespan Comparison

6. Application Suitability: Where Each Material Excels

7. Customization: Color, Shape, and Illumination

8. Installation, Maintenance, and Total Cost of Ownership (TCO)

9. Conclusion: Making an Informed Material Selection

1. Introduction

Push button switches are widely used in various technological products, ranging from heavy machinery in factories to simple TV remotes. The choice of material plays a decisive role in the long-term performance of the switch. Differences between metal and plastic directly affect the operational stability of the switch; selecting the wrong material may lead to equipment failure or additional cost losses.

This choice is essentially a series of trade-offs: metal materials offer excellent strength and a solid tactile feel, while plastic provides cost advantages and better adapts to specific application scenarios. This article conducts a detailed push button switches material comparison of these two options, analyzing from multiple dimensions such as structure, performance, and application, to provide practical references for procurement decisions and product design.

2. Material Deep Dive: Construction and Core Properties

The performance of a switch starts with its base material. Metal push button switches are usually made of steel, aluminum, or brass, which can effectively withstand external impacts; plastic push button switches mainly use ABS, polycarbonate, or nylon as raw materials. Each material has unique performance characteristics to meet different application needs.

3. Metal Push Button Switches: Engineered for Durability

Metal push button switches are designed for long-term stable operation. Stainless steel has excellent rust resistance, aluminum effectively controls weight while ensuring strength, and brass resists corrosion well in humid environments. These metal materials have high tensile strength, can withstand impacts without cracking, and have minimal deformation when temperature changes.

High tensile strength means metal switches can only break under extreme external force, a feature that gives them significant advantages in harsh environments. Thermal stability ensures they maintain stable performance across different temperature scenarios, from low-temperature workshops to high-temperature engine compartments.

3.1 Tactile Feedback and Actuation Force

Metal buttons produce a clear click when pressed. This distinct tactile feedback allows users to intuitively confirm that the switch has been activated, which is crucial in high-precision operation scenarios such as machine tool control. Its actuation force remains consistent, without a soft pressing feel.

Operators rely on this crisp actuation feedback to reduce operational errors in high-speed tasks. For example, on factory production lines, a solid pressing feel can effectively avoid misoperations. The weight of the metal further enhances this stable feedback, while plastic buttons may experience pressing deviation due to material toughness, resulting in poor tactile sensation.

3.2 Environmental Sealing Capabilities (IP Ratings)

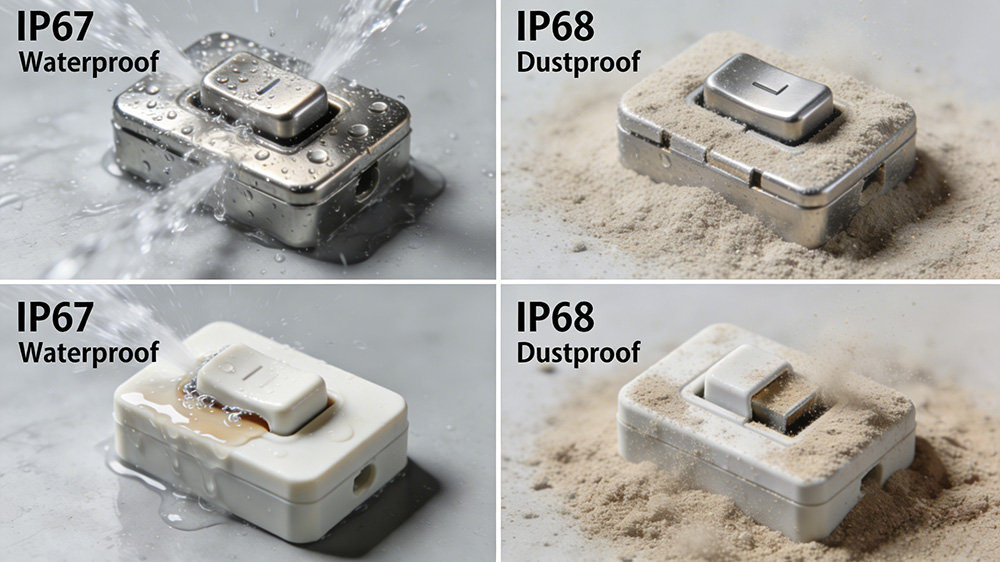

Metal housings of push button switches have excellent sealing performance, achieving high push button switches IP rating such as IP67 and IP68. They can effectively block dust intrusion, resist high-pressure water jet impacts, and remain unaffected by chemical substances in factory environments.

In the North American market, their protection performance can be certified by corresponding NEMA ratings. Metal switches are tightly connected to panels through threads, and double protection is achieved with sealing gaskets. They are widely used in outdoor equipment and will not cause short circuits even when exposed to rain or splashes.

4. Plastic Push Button Switches: Balancing Cost and Functionality

Plastic push button switches are manufactured through injection molding, which offers high production efficiency and enables mass rapid production. Among them, ABS is resistant to daily wear, polycarbonate has strong impact resistance, and nylon has good flexibility and is not easy to break.

Compared with metal, plastic materials are lighter, can be injection-molded into complex shapes, and significantly reduce costs in large-scale production scenarios.

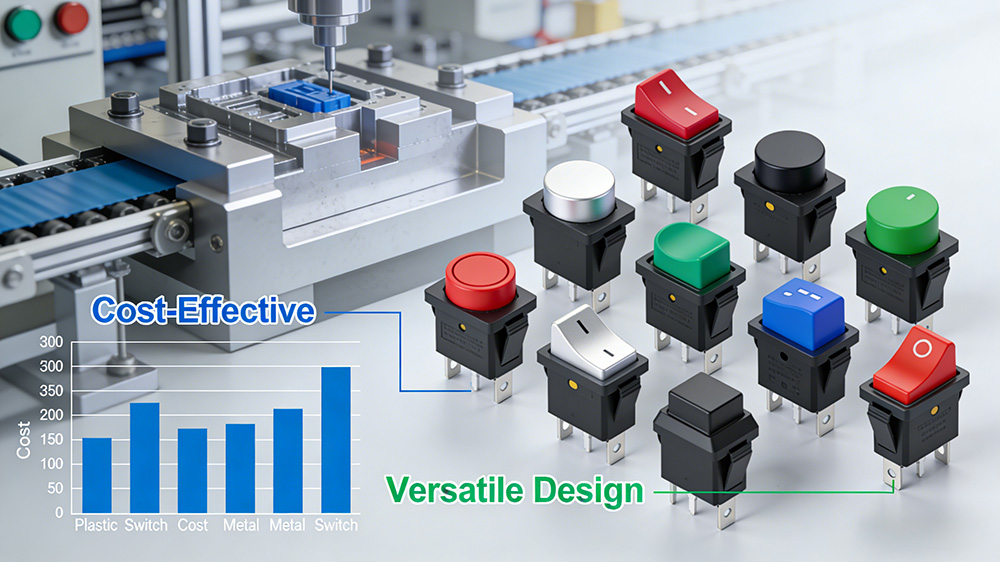

4.1 Cost-Effectiveness in High-Volume Manufacturing

Plastic materials can effectively reduce unit product costs, and their price advantage is particularly obvious in bulk purchases of high-volume plastic push button switches. Therefore, they are widely used in consumer electronic products such as remote controls. For household scenarios, there is no need to pay a premium for unnecessary metal materials, and the injection molding process also eliminates complex mechanical processing steps, further controlling costs.

For example, the total cost of mass-producing 10,000 plastic push button switches may be only half that of metal switches. This cost advantage is particularly prominent in the electronics manufacturing industry and has become a core cost control method for brands such as remote control manufacturers.

4.2 Electrical Insulation and Non-Conductivity

Plastic has excellent electrical insulation performance, making it ideal for electrical insulation push button switches. It can effectively block current conduction, has better insulation effect than metal, avoiding short-circuit risks caused by wire contact. It performs well in battery-powered equipment and simplifies the grounding process.

Even when hands are wet, plastic materials can effectively prevent electric shock accidents, a feature that makes them indispensable in medical equipment. In addition, plastic does not form conductive paths, ensuring pure signals and avoiding electromagnetic interference.

5. Durability and Lifespan Comparison

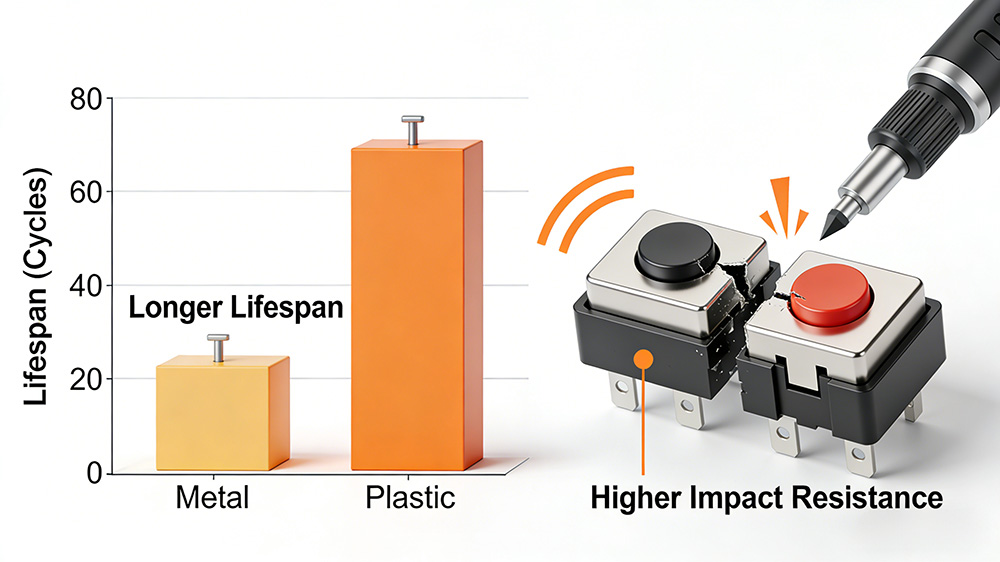

Durability is one of the core differences between metal and plastic push button switches, a key factor in evaluating push button switches durability. Service life is usually measured by the number of pressing cycles. Metal switches typically have a cycle life of more than 1 million times, while the lifespan of plastic switches varies between 100,000 and 500,000 times depending on product quality. Harsh environments in practical applications will further test the limit performance of both materials, such as high-intensity use scenarios in factory workshops.

5.1 Mechanical Stress Testing and Cycle Ratings

Mechanical stress tests simulate various losses in daily use. Metal switches can withstand more bending and pressing, and their rigid structure can effectively fix internal mechanical components; while cheap plastic switches wear out significantly faster.

High-end plastic switches can also reach a cycle life of 1 million times, but ordinary plastic switches are difficult to achieve. Data from well-known manufacturers such as APEM shows that metal switches perform better in harsh tests, especially in public scenarios where they can resist vandalism and have much higher stability than plastic switches.

5.2 Resistance to Physical Abuse (Vandalism and Impact)

Buttons in scenarios such as public kiosks often face vandalism such as key tapping and fist impacts. Vandal-resistant metal push button switches may dent but still work normally, while plastic buttons are prone to cracking and failure. In factory environments, when tools fall and hit control panels, metal materials can effectively absorb the impact force and protect internal structures.

Research data from UL laboratories indicates that metal switches have 50% higher impact resistance than plastic switches. Taking elevator buttons as an example, metal buttons can be used for years without failure, while plastic buttons require protective devices or frequent replacements.

5.3 Resistance to Environmental Degradation

Long-term exposure to chemical substances accelerates material aging. Some plastic materials may dissolve in solvents and turn yellow and brittle due to UV radiation when used outdoors; while metal materials such as stainless steel can resist corrosion from most chemical substances.

Cheap metals may have corrosion problems, but this defect can be effectively solved through alloy ratio, improving environmental adaptability.

5.4 Temperature Extremes and Thermal Cycling Adaptability

Low-temperature environments make plastic materials brittle and prone to breaking in scenarios such as freezers; when the tempe

6. Application Suitability: Where Each Material Excels

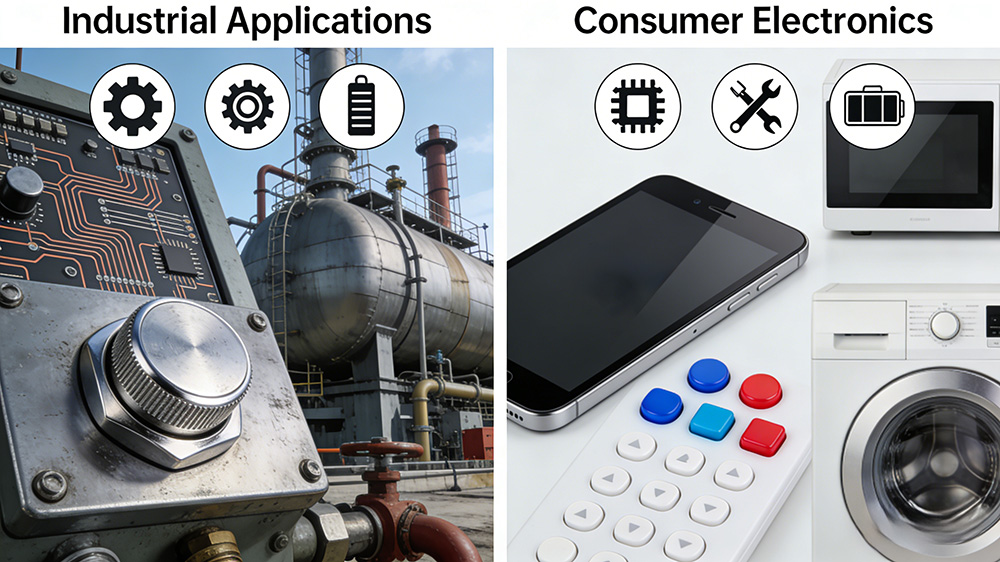

Material selection must be strictly matched to the application scenario: metal switches are preferred in industrial and heavy equipment fields, while plastic switches are more suitable for consumer electronic products. The core principle is to accurately match switch performance with usage needs—pursuing reliability in harsh environments and focusing on cost control in ordinary scenarios.

6.1 Industrial and Heavy-Duty Environments

Industrial push button switches are mostly metal, which are widely used in scenarios such as factory machinery, oil rig control panels, and outdoor signs. They can effectively resist multiple challenges such as vibration, dust, and extreme temperatures. In such scenarios, equipment reliability is crucial; shutdown failures may cause thousands of dollars in economic losses, and the stability of metal switches can minimize shutdown risks.

6.2 Safety Interlocks and Emergency Stop Devices

Safety regulations clearly require the use of metal push button switches at key safety nodes. For example, emergency stop push button switches material should be metal, as they need to have a solid actuation feel and structural strength. Metal materials can meet safety standards such as OSHA, while plastic switches may not withstand heavy pressing in emergency situations.

Safety interlock devices need to ensure that equipment can only start after the door is closed. The structural stability of metal switches can avoid misactivation and protect the safety of operators. Red mushroom-headed metal emergency stop buttons have strong visual warning properties, allowing quick identification and activation in crisis scenarios, with reliable performance.

6.3 Consumer, Medical, and Low-Profile Devices

Plastic push button switches are suitable for consumer electronics push button switches such as remote controls and toys, as well as devices such as medical monitors and game controllers. Plastic materials are lightweight, which can reduce the overall weight of the equipment (especially beneficial for the portability of medical equipment). At the same time, they can achieve low-profile designs through injection molding, fitting the ergonomic needs of handheld devices.

The lightweight feature also reduces battery consumption and extends the battery life of portable devices. In household scenarios, the appearance design of plastic switches is more flexible, which can integrate with the overall style of the product and improve the user experience.

7. Customization: Color, Shape, and Illumination

Plastic materials have significant advantages in customization. They can be injection-molded into any color, facilitating the integration of LED lighting elements, and can be shaped into complex ergonomic forms such as arcs. The customization of metal materials is limited by processing technology; although surface decoration can be achieved through painting and etching, the process is complex and costly.

For example, illuminated buttons on game controllers and skin-tone buttons on medical equipment rely on plastic materials to meet customization needs, with controllable costs for small-batch customization. Brands such as Logitech leverage the customization advantages of plastic materials to create products that combine functionality and aesthetics.

8. Installation, Maintenance, and Total Cost of Ownership (TCO)

Installation method directly affects the operational stability of the switch, which is a key part of push button switches installation and maintenance. Metal switches need to be fixed by threads for more secure installation; plastic switches adopt clamping or welding methods with higher installation efficiency. Maintenance difficulty and cost also vary by material. Push button switches TCO (Total Cost of Ownership) needs to comprehensively consider factors such as purchase price, service life, and maintenance costs, rather than just focusing on the initial purchase cost.

8.1 Installation and Wiring Considerations

Metal switches are connected to panels through threads, providing firm fixation and resistance to loosening, making them suitable for high-vibration scenarios; plastic switches are quickly clamped or soldered to circuit boards through buckles, with small size and adaptability to the installation needs of precision electronic equipment.

There are also differences in wiring methods: metal switches require additional grounding consideration due to conductivity, while plastic switches do not need such operations.

8.2 Conductivity and Grounding Requirements

Metal materials are conductive and require standardized grounding during installation. Washers can be used for isolation to avoid short-circuit risks, and additional insulation components need to be installed inside enclosed equipment. Plastic materials themselves are non-conductive, eliminating the need for additional grounding and simplifying the installation process.

Tip: Check equipment specifications before installation. Improper grounding of metal switches may cause fire hazards. Although metal switches take about 5 minutes longer to install than plastic switches, their longer service life makes them more advantageous in the long run.

8.3 Long-Term Cost Analysis

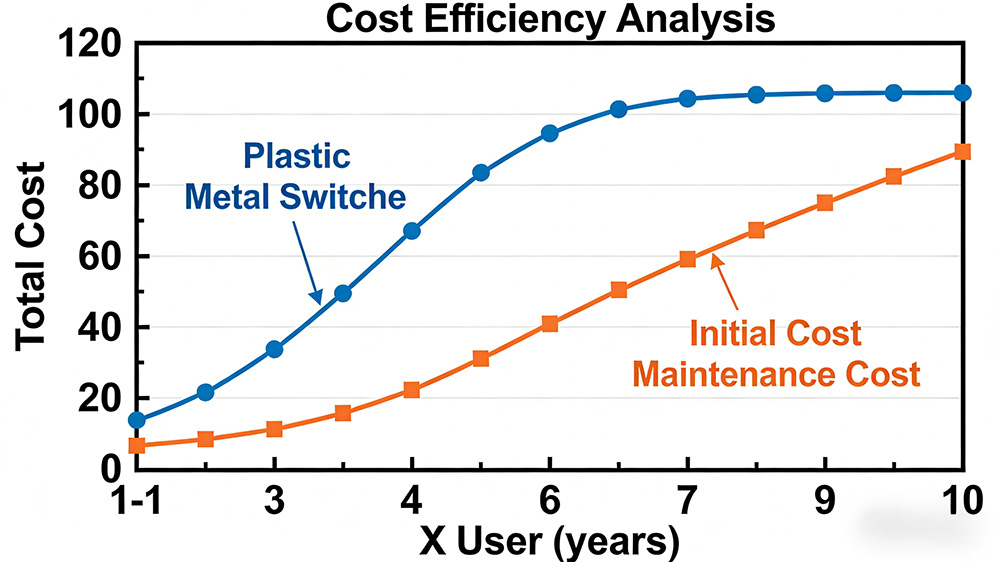

In terms of purchase price alone, plastic switches have advantages, but metal switches have a longer service life—plastic switches may need to be replaced every few years, while metal switches can be used stably for decades. In industrial scenarios, the losses caused by equipment shutdown are much higher than the purchase cost of the switch itself, so metal switches have lower TCO; in consumer products, the low cost of plastic switches is more in line with product lifecycle needs.

8.4 Repairability vs. Replacement Strategy

Metal switches have stronger repairability; internal components can be replaced individually without overall replacement. Plastic switches are mostly integrated designs and usually need to be completely replaced when damaged, increasing maintenance labor costs in the long run.

For industrial equipment, it is recommended to invest in metal switches upfront to reduce long-term costs by reducing replacement frequency; in low-intensity use scenarios such as offices, the quick replacement feature of plastic switches is more practical. A suitable replacement strategy can be selected based on usage frequency and scenario needs.

9. Conclusion: Making an Informed Material Selection

Metal push button switches excel in durability and structural strength, making them suitable for harsh environments, high-intensity use, and safety-critical scenarios. Plastic push button switches offer cost advantages and flexible customization capabilities, making them more suitable for consumer products, low-intensity use, and lightweight equipment needs. This metal vs plastic push button switches analysis helps clarify the best choice for different scenarios.

Quick decision-making can be made based on the following core dimensions:

• High IP rating or pressing cycle life exceeding 500,000 times: Prioritize metal switches

• Unit cost budget below $1 with large-volume procurement needs: Choose plastic switches

• Custom appearance, lighting function, or insulation performance as core needs: Plastic switches have advantages

• Application in harsh environments such as factories and outdoors: Metal switches are the best choice.